Let’s make soap! Are you ready?

In this post, I’m going to describe both the cold and hot process methods. Both methods follow the same initial steps, diverging at the end. Home soapmaking is most often done today using the cold process method, but hot process is what was commonly used by our great-grandmothers. Both processes actually use heat. Even in cold process, heat is applied as the fats/oils are brought to the right temperature before combining with the lye mixture. The main difference between the two methods is that no external heat is utilized further in the saponification of cold process while in hot process the saponification is actually finished over a heat source–in the method I’m going to demonstrate, a crock pot. I’ve made soap both ways now and I far prefer the hot process method. The soap is cooked through and cured right in the pot before being placed in the mold. It’s non-caustic and usable as soon as it hardens.

I’m not sure why cold process is so popular today, but I think just the term “hot” scares people who are already scared of the lye. I’m going to demonstrate both–and you can decide for yourself! Please do not take this post as your single source of soapmaking instruction. This post is intended as demonstration, encouragement, and inspiration. Get a soapmaking book or three and learn as much as you can–then get to soapmaking. It’s fun–and easy, whether you choose hot process or cold!

Read more about the different processes of making soap and what goes into soap here: Getting Ready to Make Soap: Part 1.

See all about the scary lye here: Getting Ready to Make Soap: Part 2.

And find out all about the necessary tools and utensils here: Getting Ready to Make Soap: Part 3.

If you want to develop your own recipe or test a recipe you’ve found online, use a soap calculator: SoapCalc.

If you’d like to try my first recipe to make soap, here it is!

Printer-Friendly

Printer-Friendly

Vanilla Sugar Dreams Soap:

lard–22.4 ounces or 635.029 grams

olive oil–9.6 ounces or 272.155 grams

distilled water–12.16 ounces or 344.73 grams

lye–4.24 ounces or 120.195 grams

4 vanilla beans, finely chopped or ground

1 cup white sugar

2 ounces vanilla fragrance oil (optional)

2 tablespoons cinnamon (optional)

You will have an unscented bar if you don’t add the fragrance–you may prefer that. The chopped/ground beans by themselves will not add much fragrance, but they do add pretty and delicious-looking flecks to the soap. With the chopped/ground beans and the sugar, this recipe has a light conditioning quality and a moderate amount of suds with a lovely, creamy feel that is very soft on the skin. (I love it!) The cinnamon provides a very slight hint of fragrance, but like the beans themselves, not a lot. It adds a bit more of a scrubby quality to the bar and also darkens the soap. If you prefer a lighter, less scrubby bar with clearer flecks of vanilla, leave out the cinnamon. This recipe yields approximately 3 pounds of soap out of the mold.

Vanilla Sugar Dreams soap with cinnamon.

Vanilla Sugar Dream soap without cinnamon.

CAUTION: Wear goggles and gloves any time you’re dealing with lye and while handling the soap until it tests non-caustic with a pH strip.

Note: In the excellent book Smart Soapmaking by Anne L. Watson, the author describes a temperature method as a sign that your soap is ready to pour into the mold in cold process soapmaking. I’m going to include the temperature instructions as a backup to seeing trace as some people may find that helpful. Trace is actually quite easy to recognize. While temperature-taking of the fats/oils mixture and lye mixture at the point of combination (in cold process) is important, I don’t find continuing to test the temperature through the blending process useful and, in fact, it’s a little bit of a hassle and sometimes confusing if you clearly have trace but the temps don’t add up. It’s also unnecessary–but you may want to try it. I found the evidence before my eyes of trace to be far more helpful.

On another note, I found varying directives on the temperature at combining the lye mixture and the fats/oils in cold process. Anywhere from 90-110 F to 90-130 F. I went with 90-110 as my target range.

And yet another note: If you intend to make hot process soap, taking the temperature of the lye mixture and the fats/oils mixture before combining is not necessary and you may disregard all temperature instructions here as well as the lye cooling bath. You’re going to cook it all anyway. Other than the temperature-taking, cold process and hot process instructions are the same until you get to the end, at which point I give directions for finishing each method separately. Never taking the temperature AT ALL is just one more reason to make soap using the hot process method! However, it doesn’t hurt if you do control the temperatures before combining the mixtures. Since that is the only difference between cold and hot process before the end where they diverge completely, I’ve combined the directions up to that point. Just know that if you’re doing hot process, it’s not important or required–but you can absolutely follow the cold process temperature instructions right up to the point where you go on to cook it through for hot process if you want! Up to you.

Printer-Friendly

Printer-Friendly

How to make Soap: Cold Process and Hot Process

Step 1

Gather all tools, utensils, pH strips and other supplies including your molds. Prepare your work area. Along with a large crock pot, you will need a number of bowls and utensils for holding, measuring, stirring, etc. Do not use aluminum, tin, or copper. Use stainless steel, glass, or heat-resistant plastic for your bowls and utensils. For your pot, I recommend an enamel crock pot, though you could also use a stainless steel pot and, if finishing your soap with hot process, cook it on low over the stovetop. You’ll also need a good kitchen scale, a stick blender, and a thermometer. (You can do this without a stick blender if you don’t mind stirring for a longer period of time.) For your mold, use anything you like, but don’t use aluminum, tin, or copper in cold process. (You can use absolutely anything with no caveats if you’re doing hot process.) I’m using quart-size paper milk cartons as my molds in this demonstration–make sure these are cartons with a waxy lining, not the shiny, silvery lining some have–that’s aluminum and can’t be used in cold process. (You’ll need two quart-size milk cartons for this recipe. One will be filled completely, the other only partly.) If you’re using a wooden or other mold, line it with freezer paper cut to fit. Place the molds on a heat-safe surface and cover the surface with freezer paper to catch any spills while transferring the soap to the molds. If preparing for cold process, have several old towels onhand for incubating the soap in the molds.

You will need a pot large enough for your lye mixing bowl to sit in. This is your lye cooling pot. Fill it partially with water before you get started to prepare it for the lye bath. (The cooling bath is required for cold process only, but again it doesn’t hurt if you do this step in hot process.)

Step 2

Gather and weigh the fats/oils and additives. Soapmaking experts recommend taking your measurements in grams. I weighed everything using ounces with this recipe and had no problem.

Lard.

Olive oil.

The additives–chopped/ground vanilla beans, sugar (and cinnamon, if using), and fragrance oil.

Step 3

Melt the lard in the crock pot. Once it’s melted, turn off the crock pot and add the olive oil. Let the mixture cool, testing the temperature as it goes down–you can take the crock out of the holding pot to speed the cooling if you want. The fats/oils mixture should be within the 90 to 110 F degree range at the time it is combined with the lye mixture. When the fat/oil mixture is down to 110, move on to the next step. (Return the crock to the pot, if you’ve taken it out, and put the lid on the crock pot to hold the temperature of the fats/oils steady while you prepare the lye mixture. Important: At this point, the crock pot is TURNED OFF.

Step 4

Measure the distilled water.

PUT ON YOUR GOGGLES AND GLOVES. Measure the lye. I measure my water and lye inside then take everything outside to mix. You may prefer to do everything, including measuring, outside.

Slowly pour the lye granules into the distilled water. NEVER POUR WATER INTO LYE. ALWAYS POUR LYE INTO WATER.

Stand back from the mixture so that you don’t inhale the fumes.

The mixture will be cloudy at first, then turn clear. Stir constantly until the mixture is clear and all the lye granules are dissolved.

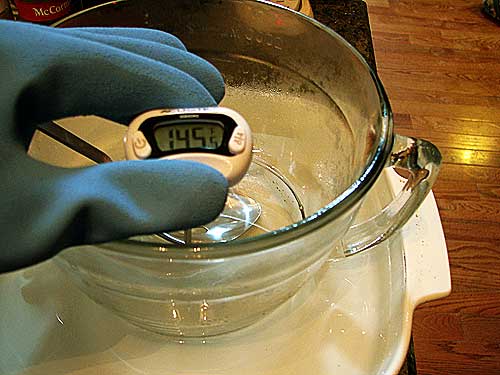

At this point, I take the lye mixture inside for the lye cooling bath. You may want to continue with the lye bath outside. Place the bowl with the lye inside the prepared pot of cold water. You are NOT pouring the lye mixture into this pot. You are setting the pot of lye mixture inside the pot to cool it. Add a few handfuls of ice cubes. Test the temperature as the mixture cools until it reaches the 90 to 110 F degree range.

At this point, also test your fats/oils to see that they are still in the correct temperature range. If not, heat the crock pot briefly. The fats/oils and lye mixtures don’t have to be at exactly the same temperature, but you want each mixture to be within the 90 to 110 F degree range at the time they are combined.

Step 5

YOU ARE STILL WEARING YOUR GOGGLES AND GLOVES. Pour the lye mixture into the crock pot with the fats/oils. (Remember that at this point, the crock pot is TURNED OFF.) Stir briefly to mix the ingredients. If using temperature as a backup for recognizing trace, take the temperature of the combined mixture now.

Place the stick blender in the crock pot, making sure the blade is completely immersed in the mixture to avoid blending air into the soap or creating splatters. I use a fairly deep crock pot–it’s a 6-quart crock pot. I prefer to use a bigger pot so the higher sides prevent even accidental splatters from getting out. Just make sure whatever pot you’re using, with whatever size recipe you’re using, the stick blender can be completely immersed in the mixture while blending.

The mixture will turn opaque and become thicker and smoother as you blend it. To avoid burning up your stick blender, blend with it on for a few minutes, then turn it off and just stir with it. Then on, then off, as you watch for the mixture to come to trace.

What is trace? Trace is the stage in soapmaking where you can draw a line across the mixture and it will remain visible for several seconds before disappearing. (Sort of like when you’re making a thick gravy or a pudding.) You can draw a line with the tip of the thermometer. You can pull the stick blender out of the mixture and see if it holds a little glop where you pulled it up. Draw a circle in the mixture. You’ll see the difference very easily.

Instead of the surface instantly smoothing out, you will see the “trace” of whatever you’ve drawn through it. Depending on the fats/oils involved, trace can usually be reached with a stick blender in 5 to 10 minutes. Hand-stirring typically takes 30 minutes.

You can back up your determination of trace by temperature. If you took the temperature of the combined mixtures before you started up with the stick blender, take the temperature again. Saponification creates heat. If the mixture has risen by at least two or three degrees F, it’s ready to pour into the mold for cold process–or move on to cooking through for hot process. (If you wait till it rises over five degrees higher, the mixture may be too thick to pour into the molds for cold process, but you can still spoon it in, so you can’t really screw this up. If you’re unsure if you’re seeing trace, blend some more and check the temperature again. Probably by the second time you make soap, you’ll feel comfortable that you know what trace is and will lose all interest in this temperature backup method.)

This is the point where cold and hot process soapmaking completely diverge. If you want to make hot process soap, skip down to the hot process instructions. If you want to continue with cold process soap, carry on right here!

Cold Process Instructions

*CONTINUE TO WEAR THE GOGGLES AND GLOVES until the soap is safely in the molds and you are wrapping it up.

Once the soap has traced, mix in your additives and fragrance oil, if using. (You would also add any soap colorant now, if using.) Mix quickly and thoroughly.

Pour the soap into your molds (or scoop it out with a big measuring cup).

With the milk cartons, you can clip the tops together with clothespins.

Cover the molds, wrapping them, top and sides, in at least two layers of old towels. In cold process, the mixture is continuing to saponify while it’s in the molds. It will actually get hotter initially before cooling off. Wrapping the molds with towels helps hold in heat during this incubation period.

Your soap will be solid in about 12 hours and ready to be removed from the molds and tested in about 24. WEAR GLOVES when removing the soap from the mold. If using milk carton molds, just tear the mold off. To test, dab a bit of distilled water on the surface of the soap. Using your glove, smear the water around to make a bit of paste with the soap and test it with a pH strip. If your strip reads between 7 and 10, the soap is no longer caustic and is safe to touch.

Cut the soap into bars and set it out to dry and “cure” for about four weeks. As it cures, it will become milder and harder.

*Use a sharp, smooth knife or a special soap cutter to cut bars.

Hot Process Instructions

STILL WEARING SAFETY GEAR! Once the soap has traced, turn the crock pot ON. Set it on Low. You can stir the mixture up now, but it’s not necessary. Put on the lid. Leave it alone. Check it periodically for progress. There is no need to stir it unless it’s spilling over the sides–which will NOT happen if you’re using a large crock pot. Note that you did NOT mix in the additives immediately after trace as in cold process.

The soap will gradually take on a waxy appearance. The edges will appear dryer than the middle as they push up the sides of the crock pot. This is okay. The edges will start folding over toward the middle.

At this point, stir it up. It should look like waxy mashed potatoes.

Test it with a pH strip. It should register between 7 and 10.

Success! The cook time will depend on the fats/oils involved. It took 1 hour and 15 minutes for me with this recipe. The soap is no longer caustic and is safe to touch. You can shed all goggles and gloves. Mix in the additives and fragrance (and colorant, if using).

Scoop the mixture into the molds.

Bang the molds down a little to settle. There’s no need to wrap and incubate. You can throw a towel (or paper towel) over it to keep off dust (or cat hair) while it cools.

As soon as it’s cooled and hard–about 12 hours–it’s ready to remove from the molds, cut into bars, and use. If using milk carton molds, just tear the mold off.

These glops that fell off the spoon onto the freezer paper became hard right away.

I made this batch using the ground vanilla beans, white sugar, and fragrance oil–but no cinnamon. See how you can see the flecks of vanilla bean. This thin piece that spilled off the spoon was hard within 5 minutes.

It’s soap! Two hours after starting to make soap in hot process, I have soap. You have to wait 24 hours before you can even think about touching it in cold process. With hot process, I can wash my hands with it right away!

That’s the beauty of hot process–it’s real soap, real fast. An extra plus is that hot process is much closer to how our great-grandmothers made soap. Only we have crock pots! Cold process is too slow for me, and I find hot process to actually be easier.

Clean up! Put all your lye mixing things in a plastic dish pan. Splash in some white vinegar and dish soap. Wash it all up. Scrape out and wipe out your pot and everything else that is soapy then wash them up. Run everything through the dishwasher. Wipe your counters down with a little vinegar and water. Tip: Wash your gloves with your hands still inside them.

Mistakes I made the first time making soap (cold process):

1. I used tap water out of the kitchen sink instead of distilled water. I’m not sure why. I had distilled water and planned to use it. When I went to measure the water, I plum forgot.

2. I had the temperatures off when I combined the lye mixture with the fat/oil mixture. It took so long for the fat/oil mixture to cool down, the lye mixture cooled too much. That’s how I learned to get the fat/oil mixture cooled down to the top of the correct range before starting up with the lye mixing. It doesn’t take long to cool the lye mixture with the cold water bath.

3. I forgot to wrap the soap molds right away, screwing up the soap incubation.

I was trying something for the first time, freaking out about the scary lye, and taking pictures. Probably, that was just one thing too many. But! I still made soap. My first batch of cold process soap, with all these mistakes, took longer to test out safe with the pH strips, but it finally did and it turned out fine. I think it must be hard to mess up making soap. So don’t worry so much!

Note: I’ve also found that mixing in additives one at a time, instead of dumping them all in at once before mixing, helps keep them from trying to clump.

Making soap has been on my personal Dare Debbie list for awhile. Let me know what you think!! I love making soap, and I’m so glad I got over the scary lye. Now you!

P.S. Cindy, who has given me much help and guidance on my soapmaking journey, has some of my “Vanilla Sugar Dreams” soap for sale at her shop, if you’re interested! (Made by her! Not me!) Visit the Chippewa Creek shop here.

P.P.S. Never make substitutions in a soap recipe without recalculating the recipe. For example, if you are a vegetarian and want to make this recipe with shortening instead of lard, you can–but you must recalculate the measurements. The only thing you can change in a soap recipe without recalculating is the additives. To make any other changes, use a soap calculator.

UPDATE: See a more simplified hot process soapmaking post here.

Grandmatotwochicks says:

Suzanne, Your soap is BEAUTIFUL!!! I can even smell it! you make it look so easy, and not so scary with the lye! Thank You for posting this for all of us to learn.

On March 25, 2010 at 2:40 am

carsek says:

Wow! That looks really easy. I’ve made soap before but I am for sure going to try this recipe. I’ve never done it in the crock pot before. My milking goat was delivered yesterday. Milk, milk!!!

As I understand all the recipes and such I’ve looked at, to make milk soap you just replace the water with milk.. Go slower adding the lye though, because the heat of the lye will turn it a carmel color. An added benefit, put a couple cakes in your basement, the mice are drawn to the lard and lye is a good mouse trap.

On March 25, 2010 at 6:17 am

Suzanne McMinn says:

carsek, I haven’t made soap with milk yet (will try it as soon as Clover gives me some!) but from what I’ve read, the milk should be frozen then taken out to thaw no more than to the slushy point. You still want it partially frozen. The lye will melt it when you add it. If you add the lye to room temperature or even completely thawed but still cold milk, you might burn it. Anyway, as I said, I haven’t tried this yet and will have to read up more on it myself before I do it. If you’re going to make soap with milk, just be sure to read up on it beforehand.

On March 25, 2010 at 8:03 am

CindyP says:

Wonderful tutorial!! Taken step by step, it’s very hard to mess up a batch of soap with the Hot Process method. Fill your crockpot with hot water and do up the dishes, but you CAN’T do that with the cold process, there’s still lye in it!

One more thing off your Dare Debbie list………what’s next?!?!?!

On March 25, 2010 at 7:39 am

Courtney KS via NY says:

Suzanne, thank you for the time and effort you put into teaching us such valuable lessons on your blog!! Such detail is much appreciated!

On March 25, 2010 at 7:55 am

ConnieH says:

Looks great and your instructions are easy to follow. Thanks!

On March 25, 2010 at 8:07 am

Miss Kitty says:

Nice Job! Really good photos of the process. Thanks, Suzanne!

On March 25, 2010 at 8:25 am

RedDragonLady says:

Suzanne: I’ll buy some from YOU as soon as you start selling! :yes: I learned a lot from your soap articles – I have always thought that all soap had to “cure”. Thanks!

On March 25, 2010 at 8:49 am

Glenie says:

I just might try this now.

On March 25, 2010 at 8:55 am

Melissa says:

Thanks for sharing this! I’m all set to make my first batch of soap. I purchased a stick blender and digital scale, got all the ingredients, and was on the verge of trying cold process soap. So glad I didn’t! I have no desire to wait for it to cure. For whatever reason, I thought cold process was easier. One question, do you have a crockpot dedicated to your soap making? Or would it be okay to use the same one I use for cooking food? : ) Melissa

On March 25, 2010 at 9:18 am

Suzanne McMinn says:

Melissa, I’m using an old crock pot that is dedicated to soapmaking only. But, I use a lot of other things–even for the lye!–and wash them up thoroughly and reuse them for cooking. I would reuse the crock pot for cooking. Items like glass, stainless steel, and enamel can be washed with vinegar and dish soap, thoroughly rinsed out, run through a dishwasher, and reused. (For example, that big glass bowl with a pouring spout you see pictured in this post that I mix the lye in? That’s glass, so no problem. I reuse that for food–and I mix the lye in that! But it’s glass. It can be thoroughly cleaned.) Some people wouldn’t be able to stand the thought of reusing the same thing for food, but for items of those materials, it doesn’t bother me. I had an old crock pot that had a broken foot on it so I have to prop it with a trivet every time I use it. It annoys me, LOL. So I’m using that one for soapmaking and I have a new one I use for cooking. I wouldn’t reuse any plastic or wooden utensils or other items for both soap and food, though, because those materials might absorb chemicals.

On March 25, 2010 at 9:25 am

Susan at Charm of the Carolines says:

Suzanne, I really, really want to try making soap at home, but I’m really, really scared of working with Lye. Is it possible to leave it out?

Susan

On March 25, 2010 at 5:12 pm

Suzanne McMinn says:

Susan, you *can’t* make soap without lye. Don’t be scared of lye. It’s NOT that scary. Just follow the safety guidelines and you’ll be fine!

On March 25, 2010 at 5:17 pm

KentuckyFarmGirl says:

I am so happy that you posted this! I also like that you added some info regarding goat milk. We get our LaMancha as soon as we get back from Spring Break next month. I ordered the Smart Soapmaking book and while I was there found a Milk Soapmaking book by the same author and ordered it also!

Thank you!

On March 25, 2010 at 7:50 pm

BuckeyeGirl says:

Well, I have used the cold process because I thought it sounded easier too… now I see the error of that and am looking forward to trying this with the hot process. Thing is, all I have is a liquid lye solution, so I have to try to figure out the correct way to use this. You’ve inspired me to figure it out though Suzanne! I can see how the hot process is much better to use and I can’t believe I ever hesitated!

You are scary smart Suzanne! :yes: :happyfeet:

On March 25, 2010 at 8:59 pm

Nursecookie says:

Suzanne, where do you get your frangrance oils? And what about those pH strips. Thanks for the tutorial. I have fallen behind and have yet to find lye. Plan to try this once I find it and some time.

On March 25, 2010 at 9:05 pm

Suzanne McMinn says:

Nursecookie, I’ve been ordering from brambleberry.com. I’m sure there are a lot of soapmaking supply companies out there if you use a search engine, but this is the one I know. I got the pH strips and the fragrance oil from them. I got lye from a hardware store, but brambleberry also carries lye if you need to order it online.

On March 25, 2010 at 10:37 pm

jojo says:

I wonder if most people who sell their soaps like the cold process because they can get pour the soap into the molds and think it looks nicer??? I’ve looked at a lot of different soap sites and rarely find a place that does the hot method. I plan on trying both though. Thank you for going the extra mile and doing both.

I did read that adding in sodium lactate, which is the sodium salt of lactic acid, makes the hot process more like the cold process in that it is easier to pour into the molds. It also went on to say that it helps makes the bars harder which makes them last longer both in the shower and on the shelf.

Your soap looks beautiful. Congratulations on your first of many soapmaking adventures.

Don’t forget to try homemade butter too! You will be as addicted as we are to it. My husband promises it! :yes:

On March 25, 2010 at 10:23 pm

Deb Turner says:

I just absolutely love your blog . I haave shown links to here so many times . Would love for you to consider joining our primitive forum group https://crowscreekprimitives.proboards.com . It is a place to come in and make friends , share recipes , crafts ,techniques and more . We are a friendly group and would love to have you .

Hugs

Deb

On March 26, 2010 at 6:42 am

Joanna Jorgensen says:

I have been buying hot & cold process soap for over a year now (love it!)& have always wanted to make it myself but thought it was too scary. (this from someone who uses a torch daily, lol) Thanks for making this not scary and relatively simple sounding.

I am ready to try it myself & I think I’ll make some cheese too.

On March 28, 2010 at 6:20 pm

Lori Kauffman says:

Two of the things I want to do this year is make soap and cheese. (And socks, but I’m in the process of doing that now.) What a nice surprise to find your blog with instructions for making soap! After reading through, it seems very straightforward and do-able. I am inspired! Will definitely be checking back!

~~Lori

On March 29, 2010 at 10:52 pm

Aedrielle says:

Yay! I’m so excited. My immersion blender came in the mail today! I bought the one you listed on Amazon. I am still waiting on my soap making book to get here and I need to get over to the hardware store and buy some Lye and some PVC tube (for my mold! I really want round soap!!) and then I can get started. I also bought some lavender flowers from mountainroseherbs.com – so I’m excited to try that, too!! :woof:

Thanks for the tutorial!!

Can’t wait for a Goat Milk Soap tutorial!! CLOVER!! :yes:

On March 30, 2010 at 9:29 pm

Momadawg says:

Your soap looks great and I love the tutorial!

Question for you – Can I use this same process (the hot) to make the Shea Butter Supreme recipe from Smart Soapmaking?

On April 3, 2010 at 11:21 am

Suzanne McMinn says:

Yes, you can use the hot process crock pot method to make any soap recipe!

On April 3, 2010 at 11:26 am

Diana H says:

Help! I’m confused about buying the lye! I went to Home Depot and they had something in a black bottle that was also in a clear plastic bag over it. It said ‘contains concentrated lye’. I couldnt find an ingredients list so I dont know if this means it contains lye along with other stuff or contains only lye. Also, this was a liquid. I didnt know if I was supposed to get liquid nor did I know if it was supposed to say ‘concentrated’. I dont want to end up putting really strange stuff in my soap.

On April 4, 2010 at 12:49 am

Suzanne McMinn says:

Diana, don’t use liquid! You need 100 percent lye and it needs to be in crystal form. Try calling around to all the local hardware stores. If you can’t find it locally, you can order it from a number of places. I know brambleberry.com has it.

On April 4, 2010 at 6:27 am

Diana H says:

Thanks! I’ll check around for the crystals!

On April 6, 2010 at 3:34 am

Jo says:

:snoopy: Have been looking for a comprehensive method, and yours is great!! Thanks.

On April 10, 2010 at 1:23 am

Cin says:

I’ve now made soap 3 times using the hot method,(in the oven,in a double boiler and finally in a crock pot), LOVE IT! Your recipe and instructions were so easy to follow, I now have a new addiction!Thanks

On April 10, 2010 at 12:22 pm

Suzanne McMinn says:

I’m glad to hear that, Cin!!!

On April 10, 2010 at 12:35 pm

Momadawg says:

Ace Hardware sell the Lye $4.99 for 16oz with the drain cleaner stuff.

I just finished making the soap, very very easy using your instructions, thanks

On April 10, 2010 at 8:44 pm

Janette Wright says:

So excited to see this, I have been wanting to do this for years! I look forward to giving it a try…thanks for the post…a good motivator.

On April 11, 2010 at 4:20 pm

lauren says:

do you just stick the ph strip into the soap at the waxy mashed potatoe stage? when I did that the strip didnt change so then I took a little bit out on a paper plate and mixed a little water with it, stuck the ph strip in it and it tested fine, is my soap ok?

On September 28, 2010 at 8:34 pm

Suzanne McMinn says:

Yes, Lauren, your soap is good! I usually use a couple strips and try it a couple ways–sticking it in there, wiping some on a strip, etc, just to double-check.

On September 28, 2010 at 8:39 pm

lauren says:

YES!! good to hear, thanks for answering back so quickly 🙂 It smells wonderful I cant wait to use it!! this could get addicting!!! LOL

On September 28, 2010 at 8:49 pm

HeatherSue says:

I made soap for the first time today!!! I got a bunch of books from the library and then ended up following your instructions because they were the clearest! I used a recipe out of one of the books because I didn’t have all of the ingredients for your soap. I love my soap! It took less than an hour in the crock pot to get to a ph level of 8. I used a little piece in the shower today and my skin is so soft! Thank you so much for the awesome instructions and the encouragement I needed to get started!

On February 28, 2011 at 2:29 pm

Betsy says:

This was a great tutorial! You have taken the scary mystery out of the soap making process. Thank you!

On May 19, 2011 at 11:46 am

bluefish1303 says:

:wave: Hi from North East Victoria in Australia

I wondered if you had to use white sugar? Could you use brown or raw? I generally use raw sugar so it’s always in the pantry.

thank you so much for sharing your creativity.

Belinda

On September 6, 2012 at 10:44 pm

Suzanne McMinn says:

Belinda, you can use other sugars!

On September 7, 2012 at 6:54 am

bluefish1303 says:

Hi again Suzanne, well today I’ve been buying the ingredients in eager expectation of making my first batch, but I’m now feeling a little jaded by it all… To buy 4 vanilla beans would have cost $23 (so I didn’t as I couldn’t afford them and I’m wondering if it will make a difference to the finished product), I can’t find fragranced oil although I was able to get an aromatherapy oil $14 for a 1 oz bottle… The ph strips cost me $25 at the hardware superstore… I haven’t done an exact work out yet of the total costs involved in my ‘whimsy’ but I’m just wondering if I should just stick to buying soap! So far, it’s cost me $55 just for 3 things I need. Luckily I have a litre of olive oil a friend gave me. I’m sorry to sound so negative but this just wasn’t what I was expecting. :no:

Kind regards

Belinda

On September 20, 2012 at 6:44 am

Suzanne McMinn says:

Belinda, I buy vanilla beans in bulk, and they are a lot less expensive that way, but if you don’t want to buy vanilla beans in bulk, you can make the soap with other additives instead (such as herbs or ground oatmeal). $14 for one ounce of fragrance oil is highway robbery!!! Try wellingtonfragrance.com for discount fragrance oils, and soaperschoice.com is also another good source for discount soapmaking ingredients, especially coconut oil is a good price there. You can get pH test strips for $6.95 on Amazon:

https://www.amazon.com/Test-Strips-Vinyl-Wand-Range/dp/B001870MG6/ref=sr_1_1?ie=UTF8&qid=1348138772&sr=8-1&keywords=ph+test+strips+soapmaking

Olive oil is cheapest at Sam’s if you can go there, if not Wal-Mart is cheapest. I don’t know anything about aromatherapy oils, by the way, or if they are suitable for soap. That is far too expensive in any case! Google soapmaking ingredients online to find discount suppliers or just start at the links I listed in this comment.

On September 20, 2012 at 7:03 am

CATRAY44 says:

Belinda, try Vanilla Products USA on Ebay. I have been buy from them for years. The beans are wonderful, and they almost always send me a pack of”extra” beans. Also, if you click on one of their products on Amazon, and scroll down, they explain about the different types of beans and how they are commonly used, how to store them, etc.

Here is an example of one of their products:

https://www.ebay.com/itm/30-Organic-Gourmet-Grade-A-Madagascar-Bourbon-Vanilla-Beans-6-7-/230765013510?pt=LH_DefaultDomain_0&hash=item35baaaaa06

On September 20, 2012 at 7:57 am

bluefish1303 says:

Thank you Suzanne and Catray44 for your replies… I guess when I get an idea in my head I like to do it right now and I’ve been showing patience for this project while waiting on kitchen scales… but it just goes to show I should do some more internet research/shopping first… I’m in Australia and probably things are just called different names over here but I couldn’t find ‘fragrance oil’… the oil I got was the one you add a few drops to an oil burner or a massage carrier oil and it was from a health food shop so is pure…

Kind regards to you all and hopefully others will learn from my mistakes… hopefully this weekend I will get this soap made! :snoopy:

On September 21, 2012 at 11:33 am

bluefish1303 says:

:snoopy: I did it! My first batch is sitting on the sink in their moulds. I had carefully done everything and was at the tracing stage when I realised I had forgotten to put the olive oil in,so in it went,gave it a good blend and carried on… Just goes to show,if I can do it,anyone can…

On September 26, 2012 at 5:30 pm

amysapothecary says:

Hi Suzanne

I made attempted your vanilla sugar dreams soap. I didn’t know which way I’d like more CP or HP so I did it both ways. At trace a took some soap aside and put it into molds to go the CP route then I cooked the rest for the HP process. My HP soap is super sticky and SOFT. So soft I can actually cut it with a butter knife. The CP stuff seems appropriately hard (it was much harder than the HP) Is this a function of HP or did I goof somehow? Thanks for your amazing posts. I am really enjoying this hobby

On May 25, 2013 at 12:44 pm

amysapothecary says:

:wave: Hi Suzanne

I made attempted your vanilla sugar dreams soap. I didn’t know which way I’d like more CP or HP so I did it both ways. At trace a took some soap aside and put it into molds to go the CP route then I cooked the rest for the HP process. My HP soap is super sticky and SOFT. So soft I can actually cut it with a butter knife. The CP stuff seems appropriately hard (it was much harder than the HP) Is this a function of HP or did I goof somehow? Thanks for your amazing posts. I am really enjoying this hobbyhttps://chickensintheroad.com/wp-includes/images/smilies/icon_wave.gif

On May 25, 2013 at 12:45 pm

calmir26 says:

Hi, thank you for your post. I am loking for home-made for a time and no-one is so detailed as yours. Thank you again and again.

I need a recipe for medicated soap (for baby skin problem dermatita)

and a moisture and creamy soap for very dry skin.

My english is not so good so I must stop here

THank you.

On February 12, 2014 at 5:37 pm

calmir26 says:

Hi Suzanne,

I’m missing the moment when yow add the sugar. When I add him?

Thanks.

On February 13, 2014 at 3:53 am

calmir26 says:

:heart: Hi again,

I read one more time the method and I found the moment when you add sugar. I think additives means chemcal for long life of the soap.

On February 13, 2014 at 4:32 am

me_chelle68 says:

just wanted to say, got up the guts to do this, have been slowly collecting necessary items, and I am hooked!!! I found you through pinterest, and love your site.first try, did vanilla sugar dreams, either the vanilla fragrance oil wasn’t appropriate, or I put in when it was too hot,but looked beautiful,lathered well, etc. Did the chocolate spa soap next, added green mp coloring, it looked good enough to eat! Thank you so much for inspiring me and others to do things ourselves, and for your detailed instructions and pictures! And Happy Birthday!

On April 13, 2014 at 2:50 pm

Kaleigh26 says:

Can I substitute Coconut Oil for the Lard?

On May 13, 2014 at 11:05 am

Suzanne McMinn says:

You can’t make substitutions in a soap recipe…… If this recipe doesn’t suit you, you need to either find another one that is professional that you do like, or use a soap calculator to calculate your own.

On May 13, 2014 at 4:42 pm